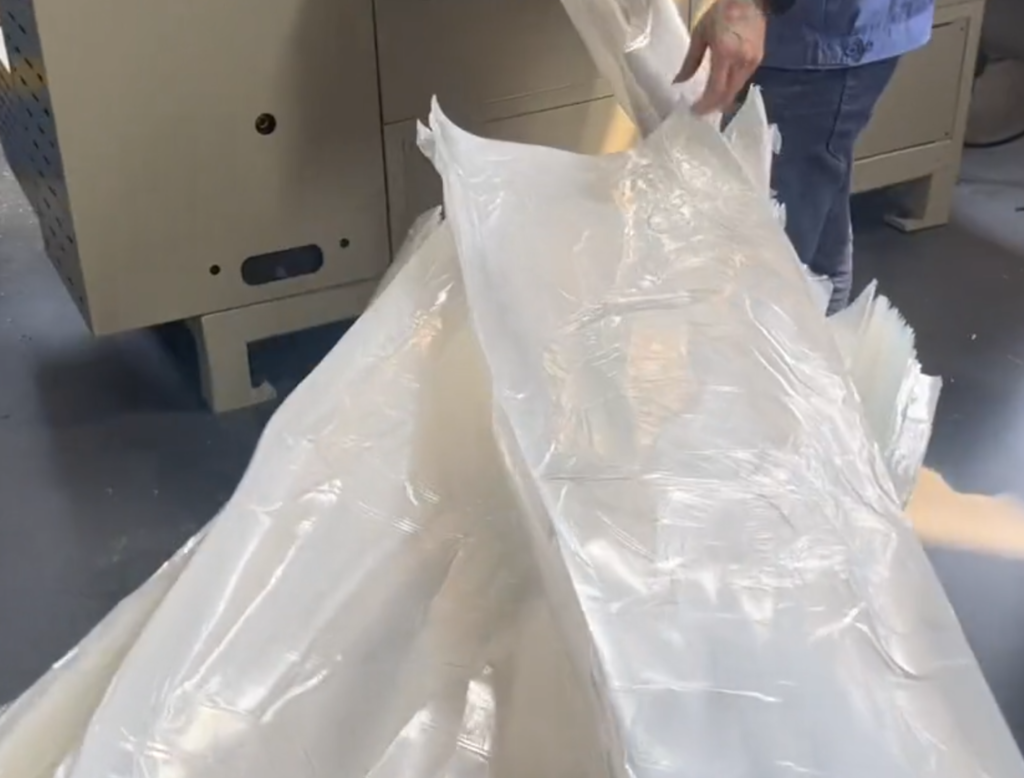

Introducing the HaoZhao HZ-100 Air Cooled Plastic Granulator, an advanced solution at the forefront of plastic recycling technology. This model, with its innovative features, is tailored to efficiently process LLDPE stretch film wastes directly from production lines, setting new benchmarks for sustainability and productivity.

The HZ-100 operates with an air-cooled system, ensuring optimal efficiency without the need for water consumption. With an increased capacity ranging from 140 to 170 kg per hour, this granulator is designed to meet the demands of high-output recycling operations. Powered by a robust 30 kW motor, the 100 mm screw diameter facilitates a seamless and precise recycling process.

Equipped with an impurities filter exchanger with a diameter of 120 mm, the HZ-100 ensures the purity of the recycled material. With an electricity consumption rate of 25 kW per hour, this machine not only maximizes efficiency but also exemplifies energy-saving technology.

Compact in size, the main machine measures 2600 * 1500 * 1600 mm, optimizing floor space while maintaining top-tier performance. Choose the HZ-100 for a granulator that combines power, efficiency, and eco-conscious design, leading the way in sustainable plastic waste management.

Upgrade your recycling process with the HaoZhao HZ-100 – where innovation meets capacity for a greener, more efficient tomorrow.